The Future of Pipe Welding: High-Efficiency Automatic Plastic Pipe Welding Machines

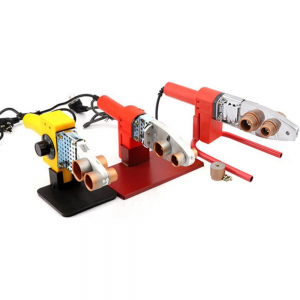

Introduction to High-Efficiency Automatic Plastic Pipe Welding Machines

High-efficiency automatic plastic pipe welding machines represent the pinnacle of welding technology, designed to automate the fusion of plastic pipes with exceptional speed and accuracy. Incorporating state-of-the-art controls, these machines precisely regulate heating, cooling, and fusion times, adapting to various pipe materials and diameters to deliver optimal welding results. Ideal for large-scale projects and demanding industrial applications, they provide a seamless, efficient workflow that significantly reduces project timelines.

Key Features and Benefits

● Automated Precision: Advanced programming ensures each weld is performed under optimal conditions, reducing the likelihood of human error and material waste.

● Speed and Productivity: With rapid heating and cooling cycles, these machines can complete welds in a fraction of the time required by manual methods, drastically increasing project throughput.

● Versatility: Capable of handling a wide range of pipe sizes and types, they are equipped for diverse applications, from water supply systems to chemical transport lines.

● Data Logging and Quality Control: Integrated diagnostics and recording functions enable real-time monitoring and historical analysis of weld quality, ensuring compliance with stringent standards.

Applications

The versatility and high efficiency of these welding machines make them invaluable for various sectors, including:

● Water and Sewage Infrastructure: For constructing robust, leak-proof networks essential for modern urban development.

● Gas Distribution Systems: Ensuring safe and reliable gas supply lines with high-integrity welds.

● Industrial Process Piping: Meeting the rigorous demands of chemical, pharmaceutical, and food processing industries with precision-welded piping.

● Mining and Offshore Operations: Providing durable solutions for the challenging conditions encountered in resource extraction and marine environments.

Choosing the Right High-Efficiency Automatic Plastic Pipe Welding Machine

When selecting a high-efficiency automatic plastic pipe welding machine, consider the following to ensure you invest in a solution that meets your specific needs:

● Capacity and Compatibility: Assess the range of pipe diameters and materials the machine can accommodate to ensure it aligns with your project requirements.

● User Interface and Ease of Use: Opt for machines with intuitive interfaces and user-friendly operation to reduce training time and enhance workflow.

● Portability and Durability: Consider the machine's mobility for on-site applications and its build quality for enduring demanding conditions.

● Support and Maintenance: Evaluate the manufacturer's support services and the availability of spare parts to ensure long-term reliability and performance.

Tips for Maximizing Efficiency

● Operator Training: Invest in comprehensive training for operators to fully leverage the machine's capabilities and optimize the welding process.

● Preventive Maintenance: Adhere to a regular maintenance schedule to maintain peak performance and prevent downtime.

● Safety Protocols: Implement robust safety measures to protect operators and equipment, ensuring a safe working environment.

● Workflow Integration: Integrate the welding machine into your overall project workflow for seamless operations and enhanced productivity.

Conclusion

High-efficiency automatic plastic pipe welding machines are revolutionizing the way we approach plastic pipe installations, offering unparalleled speed, accuracy, and reliability. By embracing these advanced solutions, businesses can achieve superior results, meeting the challenges of modern infrastructure and industrial projects head-on. With the right machine and approach, the potential for streamlined operations and exceptional quality in plastic pipe welding is virtually limitless.