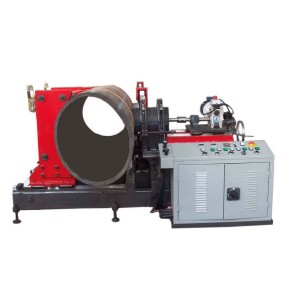

SDY-20063 Pipe Fittings Butt Welding Machine

Features

1. Removable PTFE coated heating plate with separate temperature control system;

2. Electrical planning tool;

3. Be made of lightweight and high strength material; simple structure, small and delicate user friendly.

Technical Parameters

|

1 |

Equipment name and model | SDY-200/63 Pipe Fittings Butt Welding Machine | |||

|

2 |

Weldable pipe range (mm) | Ф200,Ф180,Ф160, Ф140, Ф125, Ф110, Ф90, Ф75, Ф63 | |||

|

3 |

Docking deviation | ≤0.3mm | |||

|

4 |

Temperature error | ±3℃ | |||

|

5 |

Total power consumption | 2.45KW/220V | |||

|

6 |

Operating temperature | 220℃ | |||

|

7 |

Ambient temperature | -5 - +40℃ | |||

|

8 |

Time required to reach the welder temperature | < 20min | |||

|

9 |

Heating plate maximum temperature | 270℃ | |||

|

10 |

Package size | 1、Rack (including inner clamp), basket (including milling cutter, hot plate) | 92*52*47 | Net weight 65KG | Gross weight 78KG |

| 2、Hydraulic station | 70*53*70 | Net weight 46KG | Gross weight 53KG | ||

Product Advantages

1. The main accessories of the welding machine are made by fully automatic aluminum casting. It is lighter, more solid and smooth than the machine made by sand-casting and steel-form technology.

2. Using static plastic-spraying process, colorful,smooth surface and not easy to be damaged.

3. The main accessories of the hydraulic station are imported overseas, which could reduces the maintenance and extends the life of hydraulic station.

Why choose our factory?

Our company has advanced production equipment and strong technology. The producing process is under strict management in quality. Our products are sold around the world and highly thought of since excellent quality and perfect service at home and abroad.