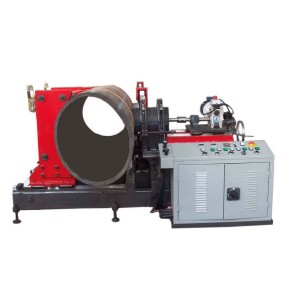

SDC800 Bandsaw Cutting Machine

Applications and features

It was designed to be used in workshop to process elbow, tee and cross these fittings, according to setting angle and length to cut pipe.

Cut pipe in any angle from 0-45°, can expand to 67.5°.

Automatic check band saw broken and stop machine to ensure operator's safety.

Strong construction, stable performance and low noise.

Hydraulic feeding, step less speed regulation.

Hydraulic claming, automatic stopping.

Simple and convenient operation and maintenance.

Specifications

● Superior Accuracy: Advanced sensors and control systems provide exact temperature regulation and pressure application, resulting in precise and reliable welds.

● Enhanced Efficiency: Streamlines the welding process, significantly reducing welding time and increasing project throughput.

● Consistent Quality: Automation minimizes human error, ensuring each weld meets high standards of quality and durability.

● User-Friendly Interface: Intuitive controls and programmable settings allow for easy operation, even for complex welding tasks.

● Versatility: Capable of handling a wide range of pipe sizes and materials, making them suitable for diverse applications.

Applications

|

1 |

Equipment name and model | SDC800 Bandsaw Cutting Machine |

|

2 |

Cutting tube diameter | ≤630mm |

|

3 |

Cutting angle | 0~67.5° |

|

4 |

Angle error | ≤1° |

|

5 |

Cutting speed | 0~250 m / min |

|

6 |

Cutting feed rate | Adjustable |

|

7 |

Working power | ~380VAC 3P+N+PE 50HZ |

|

8 |

Sawing motor power | 2.2KW |

|

9 |

Hydraulic station power | 1.5KW |

|

10 |

Total power | 3.7KW |

|

11 |

Total Weight | 2300KG |

About us

We are proud of our work and the variety of products we offer.

We are experienced in serving the Southeast Asian market, South America, European markets and African markets.

Please note that our production lead time depends on the specific project and the number of projects.

Our Services

1. One year warranty, life-long maintenance.

2. In warranty time, if nonartificial reason damaged can take old change new for free. Out of warranty time, we can offer maintenance service (charge for material cost).

3. Engineers available to service machinery overseas but all the costs to the buyer to pay.